manufacturing-quality

JBT-2019-01-mill03

JBT-2019-01-volume02

Industry Leading Quality

JBT’s company mission is to be a customer focused innovative machining company that consistently achieves and exceeds the expectations of quality and service that our customers have and always will continue to receive. JBT understands that our customers need their jobs completed on time and done correctly.

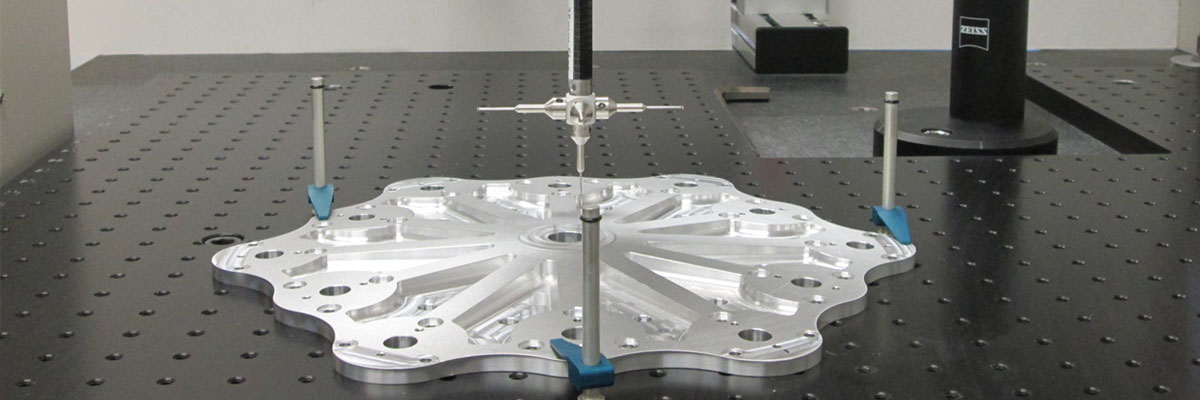

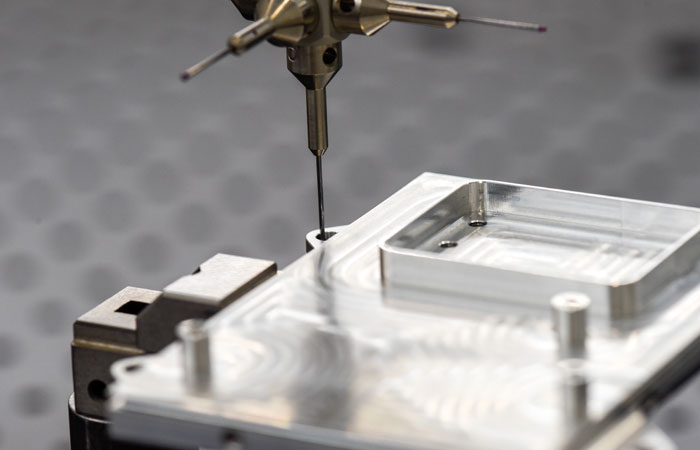

JBT, Machining has regular calibration services done on all our inspection equipment including on all of our employees hand tools. JBT has also invested in new Zeiss Contura G2 CMM and a new vision system to insure our customer receives a quality product.

- Year: 2012

- X-axis travel: 27.6 inches

- Y-axis travel: 39.4 inches

- Z-axis travel: 23.6 inches

- Scanning Technology

- Vast XT Head

- Year:2012

- X-axis travel: 16 inches

- Y-axis travel: 16 inches

- Z-axis travel: 16 inches

- Laser Sensor on Z axis

- Do ALL 3’ X 3’ X 4” granite inspection plate

- Do ALL 3’ X 4’ X 6” granite inspection plate

- Suburban Tool Master

- Mitutoyo 24-inch height gage

- Mitutoyo 18-inch height gage

- Fowler (2)

- Meyer ZZ pin set to 1 inch

- Meyer pin set to 1 inch

- Deltronics pin set to 1 inch

- Mitutoyo block set

- Zeiss Surfcom 130A Profilometer

- Caliper range from 0 – 48 inches

- Micrometer range from 0 – 12 inches

- Greenfield master set

- Greenfield shop floor set

- Caliper range from 0 – 48 inches

- Micrometer range from 0 – 12 inches

- Precision bore gages